POLYSYTRENE INSULATED ROOF SANDWICH PANELS

POLYSYTRENE INSULATED ROOF SANDWICH PANELS

|

|

|

Atermit Isopanel, which is being used widely in many countries in the world and is known as the product of the 2000 s, is successfully used in all kinds of industrial, agricultural and military structures, cold storage houses, garages, hangars, sports facilities, homes and all kinds of wide areas as roofing and cladding applications, room dividing walls and flooring applications

Atermit Isopanel is produced from EPS (Expanded Polystyrene) or rock wool filler materials which are known to be non-ignitable and are used for heat and noise insulation. Atermit Isopanel alone combines qualities such as temperature and noise insulation, lightness and durability due to its structure. Atermit Isopanel can be produced in all desired sizes and thicknesses and its length can be adjusted easily according to the needs. Atermit Isopanel can be easily transported, stored and painted in any color desired.

Guaranteeing inseparability for 15 years, Atermit Isopanel shows that it is the best quality among sandwich panels in Turkey and is therefore distinctive.

| Features: |

|

|

Can be produced with natural aluminium, pre-painted aluminium and pre-painted galvanised steel.

Pre-painted metals are coated with film for extra protection until installation.

Core can be expanded polystyrene (B-1 Grade non-ignitable) or rock wool.

Environmentally friendly. Does not contain CFC s or HCFC s. Supports air pollution prevention. Does not produce poisonous gasses if burnt.

Produced on continuous line technology. Therefore, at any desired length and thickness.

Is lighter compared to standard roofing materials. It is transported, mounted and demounted easily.

Creates dry and healthy environments, suits food production regulations. | |

POLIURETHANE INSULATED ROOF SANDWICH PANELS

POLIURETHANE INSULATED ROOF SANDWICH PANELS

|

|

|

Poliürethane Insulated Panels are composite roof and wall claddings, with rigid expanded polyurethane formed with the result of chemical reaction of Polyol and isocyanate components, and injected between two corrugated sheets. According to the type of the product, top and bottom sheets can be selected as; Aluminum, Galvanized steel, or PVC membrane

These panels provide aesthetic thermal and weather insulation solutions to the exterior shells of the buildings, and have a diverse range of application at industrial, social, agricultural buildings, factories, swimming and sports halls, grain silos, hipermarkets, malls, dwelling units and army installations.

B2 fire resistance class polyurethane is injected between the sheets with a special spray system. With the transfer of the panel to the press oven, chemical reaction

and adhesion of polyurethane to the sheet layers are completed and the composite panel form is achieved.

-Poliürathane panels are environmentally friendly products because the poliurethane is activated by pentan gas.

With trapezoidally corrugated metal surfaces, panels provide high load bearing capacities, and due to the lightness of panels , structural system costs are reduced..

With means of fast erection, workmanship and time is reduced .

- Are not effected by heat differences.

- With dosed cell structure and metal sheet surfaces, water can not penetrate into the body of the panels, can be

used safely.

- Does not generate or shelter bacterias.

- Does not dust

- Long life time |

MINERAL ROCK WOOL INSULATED ROOF SANDWICH PANEL

MINERAL ROCK WOOL INSULATED ROOF SANDWICH PANEL

|

|

|

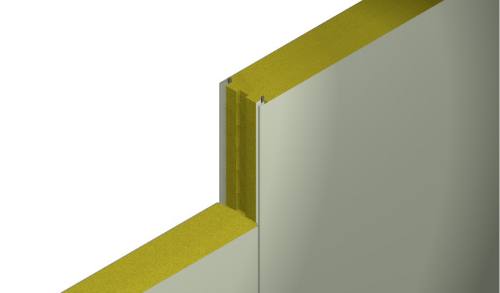

Mineral Wool Panels are preferred for buildings with high fire safety regulations, such as flammable material storage houses. With metal outer sheet and mineral wool insulation core (Fire Resistance Class A, according to DIN), a composite fire resistant system is obtained.

Besides fire resistance, these panels providing high sound and thermal insulation are environmentally clean and free of harmful substances.

Mineral wool filling is sliced in full automatic production line, fibres brought into vertical position to improve panel load bearing capacity, and placed in panels insuring to fill the corrugations |

|